Respecting the process

As with any creation, understanding and respecting the process behind it, is critical. At Prairie Plastics, that’s how we achieve the desired result in the most economical and efficient manner. For a successful process, Prairie Plastics must listen, ask questions, advise, and educate the customer as required. In turn, we ask the customer to be thorough and responsive so we can produce the desired outcome.

Prairie Plastics also understands the value of time and money for our customers. Below, we have provided a blueprint on how to achieve optimal success for all parties in the project development process. With the guidance of a careful, strategic process, any obstacles and limitations that emerge in our partnership can still be overcome to achieve success. Based on our extensive experience, we have found that the following steps help reduce waste and overall costs, and ultimately produce the desired solution in a reduced time period.

Step 1: Discovery

Whether designing a new conversion, custom packaging solution, or a thermoformed part, the process starts with accurate part data from the customer. We can accept IGES, STEP, PARASOLID, SOLIDWORKS, NX/UNIGRAPHICS, and CATIA Files. We can transfer files in whatever way is convenient for you. If we are designing packaging, an actual part would be beneficial. If electronic data and a part are not available, we can work off 2-D prints.

Whether designing a new conversion, custom packaging solution, or a thermoformed part, the process starts with accurate part data from the customer. We can accept IGES, STEP, PARASOLID, SOLIDWORKS, NX/UNIGRAPHICS, and CATIA Files. We can transfer files in whatever way is convenient for you. If we are designing packaging, an actual part would be beneficial. If electronic data and a part are not available, we can work off 2-D prints.

Material selection consideration

- End-use application

- Indoor/outdoor temperature or temperatures the application will be exposed to

- Impact and flammability requirements

- Chemical exposure

Packaging considerations

Please consider your company but also communicate with the other users of the application.

- Part orientation

- Part weight

- Can the part bear the weight of the pack?

- Ergonomics

- Material handling equipment interface – conveyors, racking, robotics, lift assists, hand jacks

- Pallet and cover components

- Labels, hand holes, drain holes

- Stripe colors

Step 2: The design process (1-2 weeks)

Prairie Plastics will compile the data and then generate not only a proposal but also select a manufacturing process and a tool layout plan based on the following criterion:

Prairie Plastics will compile the data and then generate not only a proposal but also select a manufacturing process and a tool layout plan based on the following criterion:

- Material

- Complexity

- Tolerances

- Aesthetic requirements

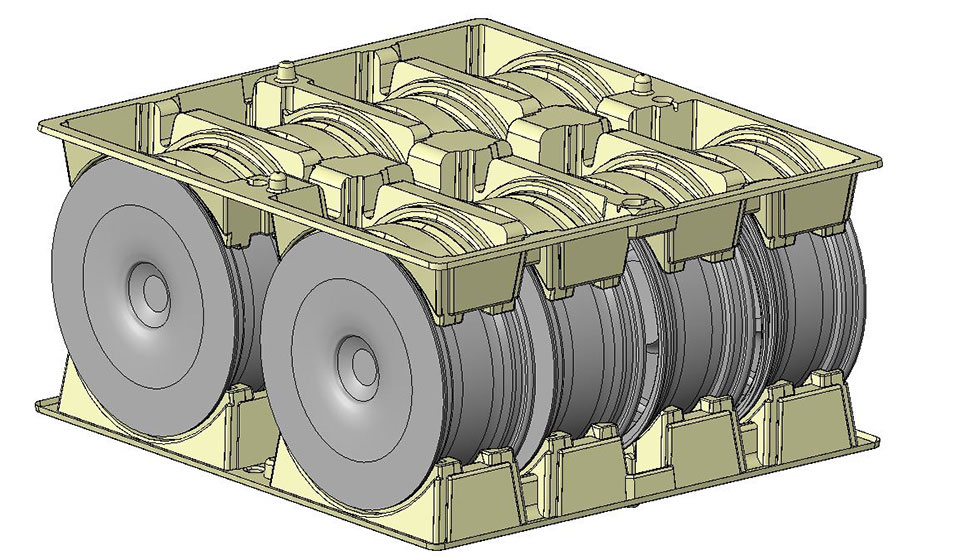

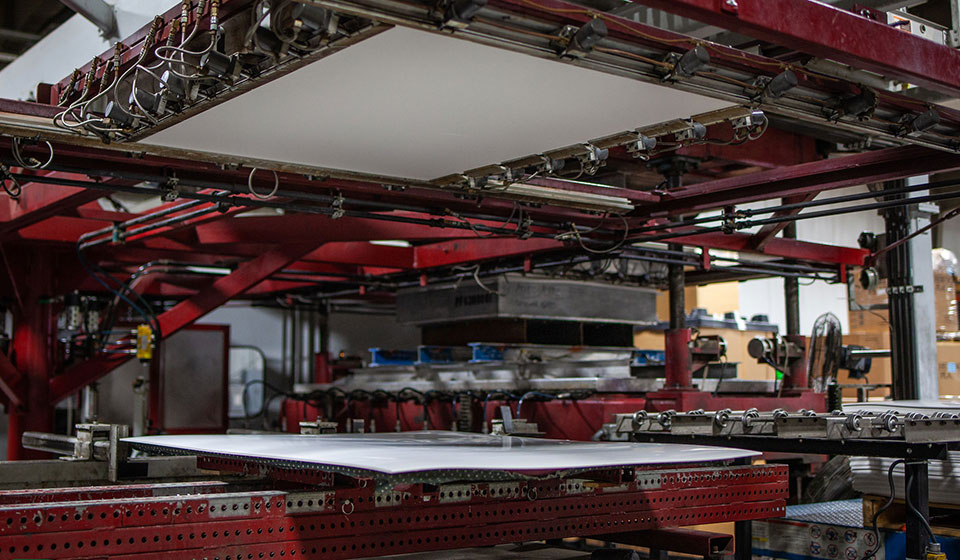

Using a combination of pressure and vacuum forming, the twin sheet forming process is used as an alternative to structural foam and blow molding to create plastic parts of superior strength. Two sheets of thermoplastic are formed on separate molds, then brought together and form welded at multiple contact points, sealing the twin sheet formed plastic parts together. This allows hollow areas to remain throughout the completed plastic part. These hollow areas can then be filled with rigid foam or inserts can be placed between the two sheets to provide additional strength.

The value of selecting twin sheet thermoforming over blow, injection, and rotational molding, is the tooling is more cost-effective and you have the potential to have greater design flexibility. Each sheet can be a different thickness and/or even different colors. In some applications the twin sheet process will allow you to even use two different materials to form a single product. The twin sheet process also allows the insertion of more elaborate hardware inside the final product before the two sheets are bonded together.

Step 3: Prototype process (3-5 weeks)

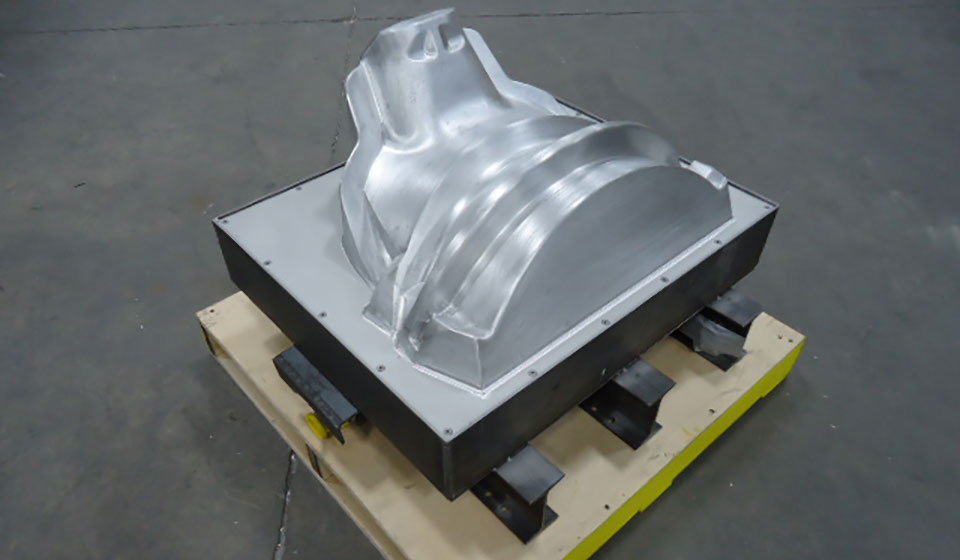

Once the partnership has approved the design, the prototype process is the most critical. In most cases, a prototype mold is necessary because the wood or epoxy mold is used to cast the aluminum production mold. This is why the samples are typically a little bigger—because they have aluminum shrinkage. It’s also less expensive and quicker to make any alterations to the mold in the evaluation process.

Once the partnership has approved the design, the prototype process is the most critical. In most cases, a prototype mold is necessary because the wood or epoxy mold is used to cast the aluminum production mold. This is why the samples are typically a little bigger—because they have aluminum shrinkage. It’s also less expensive and quicker to make any alterations to the mold in the evaluation process.

The wood or epoxy molds are fabricated in house or at an outside vendor. For the evaluation process, Prairie Plastics will then fabricate samples from the mold for the customer. The evaluation time is not included and is the responsibility of the customer. It is important that all parties involved have the opportunity to evaluate the samples. Testing can be provided at an additional cost at an outside vendor. Single-sheet sampling typically takes three weeks; twin-sheet can take as long as five weeks.

Step 4: Production tooling (3-6 weeks)

Once the partnership has approved the prototype samples, we are in the home stretch. Our production molds are manufactured at an outside facility. The customer needs to indicate what custom identification they want on their product, what color stripe, and any secondary operations such as drain holes, hand holes, labels, etc.

Once the partnership has approved the prototype samples, we are in the home stretch. Our production molds are manufactured at an outside facility. The customer needs to indicate what custom identification they want on their product, what color stripe, and any secondary operations such as drain holes, hand holes, labels, etc.

Forgetting any of these details can add time and money for the customer. We also need to discuss packaging of your product and how you want the product shipped to you. Once the tool is received from the outside vendor, we will produce production tool samples for final review. Samples are produced out of stock sheet and will not have correct striping in most cases. Twin-sheet molds typically require machining and the timing of these molds takes six weeks.

Custom color stripe options available

Blue

Brown

Green

Grey

Aqua Blue

Light Blue

Lime Green

Pink

Orange

Purple

Tan

Red

White

Yellow